- Home

- Weaving Machinery

Weaving Machinery

Weaving loom

-

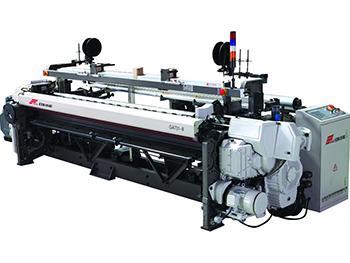

- GA731-II Rapier Loom Primarily used to weave various natural fibers (such as cotton, wool, silk, and flax), man-made fibers, and synthetic fibers, the GA731-II rapier loom is designed to produce single-width, double-width, and multiple-layer width fabrics. The machine is especially suitable for the manufacturing of large-width dyed fabrics.

-

- RFRL20 Rapier Loom RFRL20 rapier loom is designed using proven, mature technology that has been applied in various other types of Rifa weaving machines. It is a high speed weaving machine developed for energy efficiency, low vibration, and reduced noise during operation. It can also achieve step-less speed regulation.

-

- RFRL30 High Speed Rapier Loom The RFRL30 high speed rapier loom is primarily designed and used for weaving natural, synthetic, rayon, and blended yarns into various complex cloth, upholstery fabric, fiberglass fabrics, filter fabrics, and industrial fabrics for safety applications.

-

- RFRL31 High Speed Rapier Loom The RFRL31 high speed rapier loom inherits the desirable features from our older RFRL30 weaving machine. Directly driven by the cutting-edge switched reluctance motor (SRM), our rapier loom not only uses 20% less energy than conventional ones under the same weaving conditions.

-

- RFRL40 High Speed Rapier Loom This high speed rapier loom is directly driven by a super motor and is controlled by a switch reluctance machine speed regulating system. It realizes the production of textiles with high quality. Meanwhile, the machine is energy-saving overall with its exceptional efficiency.

-

- Air Jet Loom

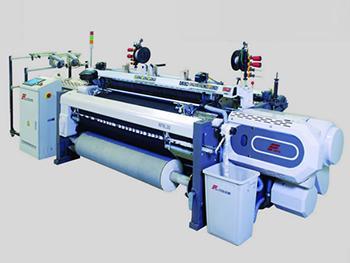

The RFJA30 high efficiency energy saving air jet loom is suitable for the production of clothing materials, home textiles, yarn dyed fabrics and some chemical fabrics where the yarn count is from 5-100. The weight of the fabric is about 40-400 grams/m2.

The air jet loom features a reasonable design to greatly reduce the vibration and noise.

-

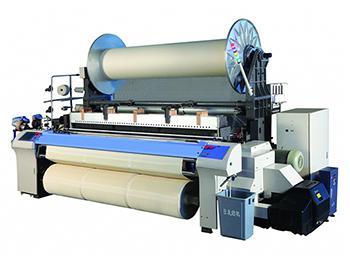

- Water Jet Loom The RFJW series water jet loom uses a virtual prototype for weft insertion design, shedding and beating up, so that the loom's vibration rate is 25% less than similar products under the same weaving conditions, and an energy consumption that is 5% lower. This water jet loom is suitable for weft insertion of spun yarn with a smooth surface and fiberglass or other filaments.

-

- High Speed Rapier Terry Towel Loom The RFTL61 high speed rapier terry towel loom is capable of carrying out free terry switching from 3 to 7 wefts. It also carries out an automatic weft density change during operation. Not only does it carry out weaving of normal terry fabrics, but the loom is also used for weaving pile-loop fabric, pique terry, wavy terry, one-sided terry ...

-

- Air-jet Terry Towel Loom The air-jet terry towel loom features a comfortable and easy operation. It improves operator comfort through the height reduction of the warp end position (During the loom leveling, the warp passes the heald wire and the pathway from the heald wire eye to the cloth-fell from the top surface of the back-rest.) An easy operation of all basic functions is achieved through use of an HD colorful touch screen human-computer interface.

-

- Rapier Terry Towel Loom

The RF50S rapier terry towel loom is suitable for fabrics of which the breadth can be divided into 8 different specifications from 190-360cm. This can satisfy the requirements of customers who produces different products at home and abroad.

The frequency converter can be applied to reduce energy consumption.

Circular Knitting Machine

-

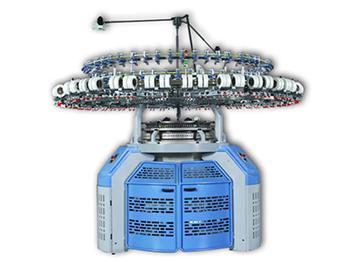

- Single Knit Circular Knitting Machine The RF SK single knit circular knitting machine is suitable for weaving of natural, synthetic, rayon, and blended yarns that will be used for underwear, tights, gym clothing and more. The structure and appearance of the knitting machine can be adjusted according to customer requirements.

-

- Double Knit Circular Knitting Machine The RF DK double knit circular knitting machine is used for the weaving of natural, synthetic, rayon, and blended yarns. It can also be used for weaving of other textile materials, such as roller goods, linsey-woolsey, small jacquard and blended fabrics. The structure and the appearance of the knitting machine can be adjusted according to customer requirements.