- Home

- Textile Machinery

- Rapier Loom

- GA731-II Rapier Loom

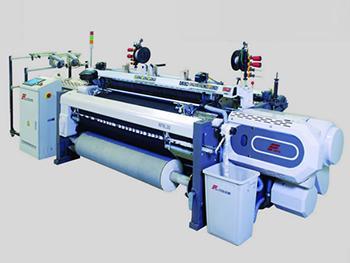

GA731-II Rapier Loom

Primarily used to weave various natural fibers (such as cotton, wool, silk, and flax), man-made fibers, and synthetic fibers, the GA731-II rapier loom is designed to produce single-width, double-width, and multiple-layer width fabrics. The machine is especially suitable for the manufacturing of large-width dyed fabrics.

Reed Width

Nominal reed width: 150, 190, 210, 230, 260, 280, 320, 340, 360, 380, 420, 440, 460

Loom Speed

190cm (approximate reed width) 312~430rpm

280cm (approximate reed width) 232 ~320rpm

320cm(approximate reed width) 224 ~300rpm

380cm(approximate reed width) 195 ~280rpm

Yarn Number(Range)

Staple Fiber: 5 ~500

Filament Fiber: 1.7 ~500

Maximum Weft Insertion Rate: 1000m/min~1200m/min

Maximum Power: 4.6kw

Weft Density (Range): 30 ~800picks/10cm

Warp Beam Disc Diameter: 800cm

Maximum Cloth Take-up Diameter: 550cm

| Weft Selection | Electronic weft selection 4/6/8 colors |

| Warp Let-off | Positive, continuous warp let-off |

| Take-up | Positive, continuous take-up |

| Warping Stop Device | Electrical contact point type |

| Automatic Weft Pick Finding System | Automatic pick finding and weft bar |

| Shedding Mechanism | Dobby Shedding |

| Electrical Control System | Single chip micro-computer control |

| Weft Beat-up Mechanism | Conjugate Cam |

| Weft Drawing-in | There are two rapiers on either side of the loom while only one weft insertion device is fitted to the one side of the said loom. One rapier carries the weft pick halfway across the warp width where the other rapier picks it up and pulls it the rest of the way. The motion of the rapier is created by the conjugate cam. |

| Weft Protector | Piezoelectric transducer for weft detection |

| Selvedge type | Leno selvedge. In addition to the selvedge forming device, the loom can also be equipped with a selvedge tuck-in device and selvedge melting device. |

| Maximum quantity of heald frames | 20pcs |

| Lubrication System | The main transmission mechanism is lubricated by oil bath. For other mechanisms, lubricating oil is forced regularly. |

- The compact design of the loom makes for simple operation and easy replacement of fabrics. The loom is highly automated and suitable for a wide range of weaving applications.

- The micro-computer control system features a liquid crystal display. It is utilized to perform various automatic functions. For example, in the event of warping and weft breakage, the loom can be automatically stopped. Further benefits of this control system include automatic pick finding, fault detection, and weft picking.

- The rapier loom adopts a positive dobby shedding system in which the shedding motion is created by the movement of the heald frame. Dependent on the fabric weaving design, we use the pre-designated punched paper or pre-set program to control the rising and lowering movement of the heald frame. This shedding mechanism can also be equipped with the electronic dobby.

- The weft drawing-in mechanism features two rapiers and one weft pick feeder on one side of the loom. Weft insertion is carried out by an assembly of a conjugate cam, flexible rapier band, and weft gripper. One gripper carries the weft pick to the center of the warp width. Meanwhile the other gripper moves from the opposite side to the center. The two grippers meet and the weft pick is transferred from one gripper to the other. The whole drawing-in process is controlled by the optimized, high-precision conjugate cam, which regulates the motion of the rapier and ensures consistent high tension of the weft pick, reliable weft transfer, and stable operating at high rotational speed.

- The weft beating mechanism operates with the conjugate cam driving the shortened sley (weaver's reed) sword. The inertial force generated by the dents of the reed is used to push the weft forward into the fell during up beats. Compared to other motions, the inertial motion does not generate impact or require any energy consumption. Likewise, the motion of the conjugate cam is utilized in the weft drawing-in process is also transferred by the movement of the shortened sley sword. This motion transmission assembly ensures sufficient beat-up force when weaving high-density and heavy-weight fabrics.

- The positive-type warp let-off mechanism adopts multiple regulatory systems to ensure the warp is evenly let-off under consistent tension.

- The cloth take-up mechanism is made up of a worm wheel, worm screw, and chain wheel, which transmit the torque necessary to drive the take-up roll for continuous winding-forward of the fabric.

- The weft color selection system allows a maximum of 8 different colors of weft to be woven. The electronic weft selection device and mechanical weft selection device are both available to choose from.

- The power of the 4kw main motor is transmitted to other mechanisms of the loom via the electromagnetic brake and clutch. Work in cooperation with the electrical control system, the electromagnetic brake and clutch can precisely control the motion of the startup and stop at a designated location, and inching forward.

- The rapier loom comes with a leno selvedge twisting device, which can work in cooperation with a selvedge tuck-in device or selvedge melting device.

- Oil bath lubrication is applied to the main transmission wheel while forced lubrication method is adopted to lubricate the bearing of the pendulum shaft. Sealed bearing is used on the parts where oil bath lubrication is rendered unusable.

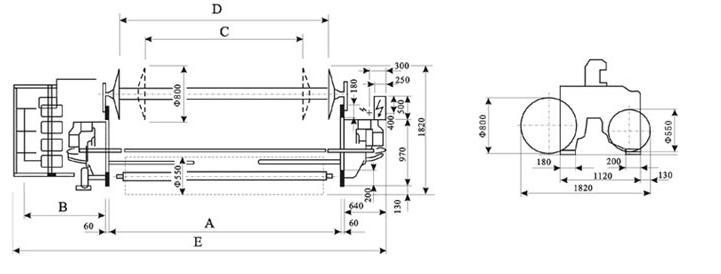

| Reed Width (cm) | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) |

| 150 | 1910 | 1193 | 700 | 1510 | 4430 |

| 190 | 2310 | 1193 | 1100 | 1910 | 4830 |

| 210 | 2510 | 1193 | 1300 | 2110 | 5030 |

| 230 | 2710 | 1193 | 1500 | 2310 | 5230 |

| 260 | 3130 | 1193 | 1800 | 2690 | 5650 |

| 280 | 3330 | 1193 | 2000 | 2890 | 5850 |

| 320 | 3730 | 1193 | 2400 | 3290 | 6250 |

| 340 | 3930 | 1193 | 2600 | 3490 | 6450 |

| 360 | 4130 | 1193 | 2800 | 3690 | 6650 |

| 380 | 4330 | 1193 | 3000 | 3890 | 6850 |

| 420 | 4730 | 1193 | 3400 | 4290 | 7250 |

| 440 | 4930 | 1193 | 3600 | 4490 | 7450 |

| 460 | 5130 | 1193 | 3800 | 4690 | 7650 |

Drawing on decades of loom manufacturing experience, we now present customers with a proven design with the GA731 rapier loom. This outstanding loom incorporates new technology which explains why it can have such unique features such as stable performance, simple operation, multiple functions, and high price performance ratio.

To fulfill the market demand while considering the diverse features of different fabrics, we have developed several series of special looms on the basis of the GA731 type. These include the jacquard loom, jute loom, industrial fabric loom, sunscreen fabric loom, and net fabric loom, among various others. All the said machines have been well commented on by our clients. Additionally, our loom can be custom built to your individual requirements.

Shandong Rifa Textile Machinery Co., Ltd.

Contact Person: Mr Zhao Zongfa

Tel.: +86-635-2999585

Fax: +86-635-8516735