The RFJA20 air jet loom is used to weave various natural, synthetic, rayon(manufactured) and blended fiber yarns into apparel, upholstery, and industrial fabrics.

Newly Added Functions Relative To RJFA10

1. The state-of-the-art electrical control system

2. Creative design of positive warp let-off mechanism

3. Breakthrough design of weft battening mechanism ensures the weft is consistently tensioned during weaving while there is little vibration generated by the beating-up tool.

4. The loom has as standard the double back beam which gives the warp its let-off motion.

5. Energy-efficient solenoid valve(electromagnetic valve)

6. Domestic pioneering weaving guidance system

| Item | Specifications | Optional Components |

| Reed Width | Nominal Reed Width: 150, 170, 190, 210, 230, 250, 280, 340, 360, 390cm | |

| Effective Reed Width: 0 ~ 60cm subtracted from the nominal reed width value which ranges between 150cm and 250cm. or 0 ~ 80cm subtracted from the nominal reed width value which is 280cm or the above. |

|

|

| Weaving Capacity | Staple Fiber: Ne100 ~ Ne5 | |

| Filament: 50D ~ 900D | |

|

| Weft Selection Device | 2, 4, or 6 colors of weft | |

| Power | Electromagnetic brake to control the loom to stop at the designated point. | |

| Starter Motor: 3.0kw (for cam shedding system) 3.7kw(dobby shedding system) 6.5kw(jacquard shedding system) |

|

|

| Push buttons (operated by two hands) | |

|

| Weft Insertion Device | Main nozzles and aide nozzles | Relay nozzles |

| Profiled Reed | ABS Weft Brake | |

| Aide Hoses | |

|

| Shedding System | Negative cam shedding system: 8 heald frames(maximum) | |

| Crankshaft shedding system: 4 or 6 heald frames | |

|

| Positive cam shedding system: 8 heald frames | |

|

| Dobby shedding system: 16 heald frames(maximum) | |

|

| Jacquard shedding system | |

|

| Warp Let-off | Electrically controlled, continuous, positive warp let-off motion | |

| Single warp beam(for loom with reed widths below 250cm) | Left and right warp let-off axles as well as upper and lower warp let-off axles | |

| Positive warp let-off motion | |

|

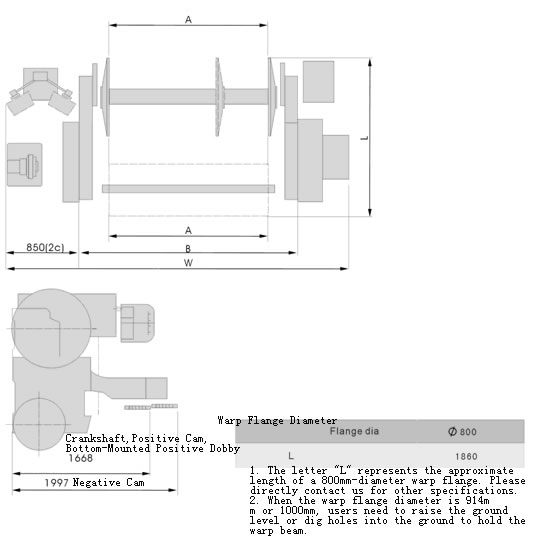

| Warp flange diameter: Ф 800mm | Φ914mm, Φ1000mm | |

| Cloth Take-up | Electronic cloth take-up | Mechanical continuous cloth take-up |

| Weft density: 25 ~ 205 picks/inch (for mechanically controlled cloth take-up) 25 ~ 300 picks/inch(electronically controlled cloth take-up) |

|

|

| Maximum cloth roll diameter: Ф 600mm(for cam, dobby, jacquard shedding system) Ф 520mm(for crankshaft shedding system) |

|

|

| Weft Beat-up | Weft beat-up mechanism with multiple sley swords and crankshaft(for power transmission) | |

| Weft beat-up mechanism with four connection rods(for beating narrow-width yarn) Weft beat-up mechanism with four connection rods(for beating large width yarn) |

|

|

| Weft Length Measurement and Weft Accumulator | Vibration type weft accumulator | Electrically controlled drum-shaped weft accumulator |

| Filling Supply Stand | Floor mounted for 4 packages (2 colors) Floor mounted for 8 packages (4 colors) |

|

| Selvedge Formation | Selvedge forming device with planetary gears | |

| Waste filling Removal | Catch cord type (3-roller type) | |

| Weft Shearing | Mechanical weft shear | |

| Lubrication | The main transmission system is lubricated in the manner of oil bath while the other transmission mechanisms are lubricated by forcing oil into them. | Automatic Centralized Lubrication |

| Stop Protector | Weft stop protector: photoelectric weft detector, double detector | |

| Warp stop protector: with 6 rows of electrical contact points | |

|

| Other stop-motion mechanisms available to stop the loom automatically if the selvedge breaks. | |

|

| Loom Stop Display: When the loom stops, the 4 color LED light will be turned on. The reason which causes the loom to stop will be displayed on the human-machine interface. | |

|

| Automatic Functions | Control system: with micro-computer (data setting, automatic control, monitoring, self-diagnosis function) | |

| Broken weft finding device: automatic pick finder | |

|

| Motion of inching forward via frequency converter(forward and reverse rotation) | |

|

| Monitor output terminal | |

|

| Memory card system | |

|

| Automatic jetting control | |

Note

1. The letter "L" represents the approximate length of a 800mm-diameter warp flange. Please directly contact us for other specifications.

2. When the warp flange diameter is 914mm or 1000mm, users need to raise the ground level or dig holes into the ground to hold the warp beam.

Features

1. The weaving guidance system monitors the operating status of the loom and guides it to adopt the most suitable process for weaving quality fabric. Based on the air jet loom condition and weave specifications, the system can automatically set appropriate parameters. In addition, the automatic set-mark prevention setting system and weft insertion parameters setting system have been improved for more efficient and safer operation.

2. The state-of-the-art positive warp let-off mechanism is utilized to give improved tension to the warp and fit the specific request for high speed operation. This mechanism is usually fitted to the external of the loom wall panel so as to correct the installation eccentricity error.

3. The box-shaped wall panels on both sides of the air jet loom as well as the cross beam are made with high-rigidity materials, providing durability and vibration isolation during high speed weaving operation. The rocking shaft comes with middle bracings for support and the vibration absorber, providing for smooth, powerful beating up motion based on computer analysis. Vibration isolation means there is little vibration that can be felt by the loom during high speed weaving, thereby ensuring stable battening operation and quality fabrics.

4. The high rigidity loom frame, large diameter weaving gear shaft, and positive warp let-off drive shaft which is installed within the lubricating oil bath container, make for high speed weaving operation and are fit for the purpose of weaving high-density weaves.

5. For effective warp let-off motion, the loom adopts double back beam to keep a consistent, even tension across the warp and throughout the weaving process. This kind of beam can be used to weave fabrics with different densities and weights.

6. The new solenoid valve incorporates a recirculation chamber, which is highly responsive. As well as carrying the weft yarn across the warp sheet to the exact location, the air jet can do so via creating high speed, compressed air with stabilized air pressure. The integrated design of front beam and air slot is directly connected with the solenoid valve, which shortens the distance between the valve and nozzle thereby reducing air consumption.

| Nominal Reed Width cm (inch) | 190(75) | 210(83) | 230(91) | 250(98) | 280(110) | 330(130) | |

| W (2C ) | Crankshaft Shedding System | 3950 | 4150 | 4350 | 4550 | 4850 | 5350 |

| Negative Cam Shedding System | 4090 | 4290 | 4490 | / | / | / | |

| Positive Cam Shedding System(SATUBLI:1661) | 4330 | 4530 | 4730 | 4930 | 5230 | 5730 | |

| Bottom Mounted Positive Dobby Mounting System (SATUBLI:2861,2871) | 4430 | 4630 | 4830 | 5030 | 5330 | 5830 | |

| A | 1900 | 2100 | 2300 | 2500 | 2800 | 3300 | |

| B | 2540 | 2740 | 2940 | 3140 | 3440 | 3940 | |

| Model NO. | RFJA 20 |

| Certification | ISO |

| Type | Weaving Machinery |

| Export Markets | Eastern Europe, Southeast Asia, Mid East, Eastern Asia |

| Trademark | RIFA |

| Packing | Wooden Pallet |

| Standard | Reed width: 190cm ~ 390cm |

| Origin | Liaocheng City, Shandong Province , China |

| HS Code | 8446305000 |

| Production Capacity | 1200sets/Year |

Related Names

Synthetic Fiber Weaving Equipment Supplier | Garment Material Making Machine | Industrial Textile Production Solution