The RFJA12 air jet loom is designed to maximize production for glass fibers. All its systems and mechanisms have been specifically constructed to facilitate the weaving of glass fibers. Those include the novel electrical control system, powerful weft beating mechanism with four connection rods, cloth take-up roller that eliminates bias filling, highly effective weft insertion assembly, negative warp let-off mechanism, suction unit, advanced cloth take-up mechanism, temple(stretcher), and selvedge shear.

Features

1. To construct an automatic control system, we use the computer which runs 32-bit version of Windows operating system to send, gather, and correct the process parameters. This control manner does not require human operation while allowing for digital management and monitoring network. Not only does this control system provide abundant information, but it also has twice the use life of the traditional intelligent keyboard.

2. Based on the characteristics of glass fiber, the computer optimized design of weft battening mechanism with four connection rods is introduced into the loom. With each beating up operation, the short-stroke reed reduces the distance that it has to travel to press the weft yarn against the cloth fell while generating little vibration and permitting longer time spent on weft insertion. Short stroke also allows the reed to give strong beating force during high speed operation of the loom, with more assurance to yield quality fabrics.

3. The rolling type cloth fell temple (stretcher) and cloth press roller eliminate the bias filling and ensure the fabric keep its tension and width while being transferred from the temple to the cloth transfer roller. There are friction materials wrapped around the surface of the cloth transfer roller and cloth take-up roller to avoid any press mark incurred by the cloth.

4. The specifically designed weft accumulator, main nozzle, aide nozzle, and relay nozzle can protect the glass fiber weft yarn from damage as well as decrease the wear of weft insertion components caused by the yarn.

5. The electronically controlled double back beam for warp let-off motion can measure out the exact warp tension and keep it at a proper level. The highly responsive AC servo motor precisely controls the let-off speed, thus ensuring the warp yarn quality.

6. The highly effective suction device sucks away the fiber fines in the air produced during weaving, thereby creating a fiber-free working environment.

7. The combined control technology of AC servo motor and angular displacement sensor assures the cloth to be tightly tensioned. The big cloth take-up roller requires little standing room, and allows a maximum 800mm-diameter cloth roll to be wound on it

8. Given the high hardness of the glass fiber, we have designed this chopping shear to remove the redundant warp ends. Such a shear requires little production cost as it gives good cutting performance and long use life.

| Item | Specifications | Optional Parts |

| Reed Width | Nominal reed width: 150cm, 170cm, 280cm, 340cm | |

| Effective reed width: 0 ~ 60cm taken away from the nominal reed width.( for the loom with a reed width ranging between 150~250cm) 0 ~ 80cm taken away from the nominal reed width(for the loom with a reed width above 280cm) |

|

|

| Weaving Capacity | Staple fiber: Ne100~Ne5 | |

| Filament fiber: 50D~1000D | |

|

| Weft Selection | Single color double color | |

| Power | The electromagnetic brake is responsible for stopping the car at the designated point. | |

| Super starter motor: 2.2kw(crankshaft shedding system) 3.0kw(cam shedding system) |

|

|

| Hand-operated push buttons | |

|

| Weft Insertion | Main nozzle, aide nozzle, stretching nozzle | |

| Profiled reed | |

|

| Aide hoses for the main nozzle | |

|

| Shedding System | Crankshaft shedding system: 2, 4, or maximum 6 heald frames | |

| Positive cam shedding system: maximum 8 heald frames | |

|

| Warp Let-off | Electrically controlled continuous warp let-off motion | |

| Single warp let-off axle (for reed width below 250cm) | Single or double warp let-off axle (for reed width above 250cm) | |

| |

|

|

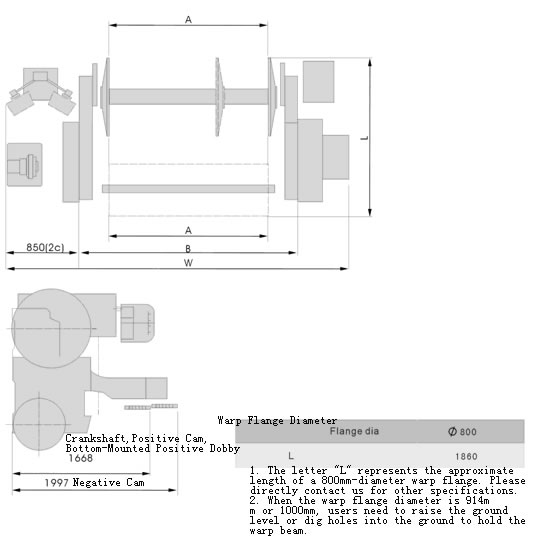

| Warp flange diameter: Ф 800mm or 1000 mm(optional) | |

|

| Cloth Take-up | Mechanically controlled continuous take-up motion | Electronically controlled take-up motion) |

| Weft density: 25 ~ 205picks/inch(mechanically controlled take-up motion) 25~300picks/inch(electronically controlled take-up motion) |

|

|

| Maximum cloth roll diameter: Ф 800 mm(electronically controlled take-up roller installed within the loom) |

External take-up roller designed for winding in large diameter cloth roll. | |

| Weft Battening | Weft beating-up mechanism with the crankshaft and multiple sley swords. | |

| Weft battening mechanism with four connection rods(for small weft width) Weft battening mechanism width six connection rods (for large weft width) |

|

|

| Weft length measurement and weft accumulator | Electrically controlled drum-shaped weft accumulator with weft braking device. | Vibration type weft accumulator |

| Filling Supply Stand | Floor mounted for 2 packages (single color) floor mounted for 4 packages (2 colors) |

|

| Selvedge Formation | Selvedge forming device with planetary gears | |

| Waste Filling Removal | Waste selvedge take-up device with gears | |

| Weft Shearing | Mechanical weft shear or professional weft shear for glass fibers | |

| Lubrication | The main transmission system is lubricated in the manner of oil bath while the other transmission mechanisms are lubricated by forcing oil into them. | Automatic Centralized Lubrication |

| Stop Protector | Weft stop protector: photoelectric weft detector, double detector | |

| Warp stop protector: | Electrical contact type with 2 rows of warp stop devices | |

| Other stop-motion mechanisms available to stop the loom automatically if the selvedge or waste selvedge breaks. | |

|

| Loom Stop Display: When the loom stops, the 4 color LED light will be turned on. The reason which causes the loom to stop will be displayed on the human-machine interface. | |

|

| Automatic Functions | Control system: with micro-computer (data setting, automatic control, monitoring, self-diagnosis function) | |

| Broken weft finding device: automatic pick finder | |

|

| Motion of inching forward via frequency converter(forward and reverse rotation) | |

|

| Monitor output terminal | |

|

| Memory card system | |

|

| Air jet control(AJC) | Filling insertion control(FIC) |

| Nominal Reed Width cm (inch) | 150 | 170 | 280 | 340 | |

| W (2C) | Crankshaft Shedding System | 3550 | 3750 | 4850 | 5450 |

| Negative Cam Shedding System | 3690 | 3890 | / | / | |

| Positive Cam Shedding System (SATUBLI:1661) | 3930 | 4130 | 5230 | 5830 | |

| Bottom Mounted Positive Dobby Shedding System (SATUBLI:2861,2871) | 4030 | 4230 | 5330 | 5930 | |

| A | 1500 | 1700 | 2800 | 3400 | |

| B | 2140 | 2340 | 3440 | 4040 | |

| Model NO. | RFJA12 |

| Certification | ISO |

| Type | Weaving Machinery |

| Export Markets | Eastern Europe, Southeast Asia, Africa, Mid East, Eastern Asia |

| Trademark | RIFA |

| Packing | Wooden Pallet |

| Standard | Reed width: 150cm ~340cm |

| Origin | Liaocheng City, Shandong Province , China |

| HS Code | 8446305000 |

| Production Capacity | 1200 Sets/Year |

Related Names

Yarn Processing Device | China Weaving Equipment Trader | Loom using Air Jet Technology