The RFRL31 high speed rapier loom inherits the desirable features from RFRL30 weaving machine. Directly driven by the cutting-edge switched reluctance motor(SRM), our rapier loom not only uses 20% less energy than conventional ones under the same weaving conditions, but it also gives higher power factor while yielding quality fabrics. It's definitely an advanced world-level weaving machine.

Energy Efficiency

The use of switched reluctance motor eliminates the need for transmission clutch and drive belt. The powerful, effective electronic switching system allows the motor to consume less energy, reduce the failure rate, and decrease maintenance cost.

Novel Transmission Mechanism for Shedding System

The warps are given shedding motion by the switched reluctance motor. Weft-finding motion is precisely controlled by the CPU and SRM. All these control features ensure reliable, stable functioning as well as reduces cost spent on shedding system maintenance.

Advanced SRM Electronic Switching System

The rapier loom rotational speed can be freely set on the operation interface where a wide range of speeds are available. Thanks to the electronic switching system, the loom can achieve rapid start-up, accurate braking to the designated position, step-less speed control, and automatic speed changing. Changing weaving speed according to the requirements of different creating processes can effectively reduce yarn breakage and set mark thereby making the loom suitable for various weaving applications.

Cutting Edge CPU

The CPU numeric control system utilizes the CAN-bus system to monitor and manage all the functioning modules therein. The big screen displays loom operating status in graphic form. The function keys set on the operating table allows ease of operation. Users can use the SD card to insert production program into the computer or use the RAM card to upload the production data to the internet.

State-of-the-Art Centralized Lubrication System

The double centralized lubrication systems are both controlled by the micro-computer. Where key parts on the loom need to be lubricated, the system will force the lubricating oil spray into them. Its high-precision oil pressure sensor can monitor and display the running condition of lubricating system, in an attempt to ensure the proper functioning of the loom.

| Item | Specifications | Optional Configurations | |

| Reed Width | Nominal reed width: 170cm, 190cm, 200cm, 220cm, 230cm, 240cm, 260cm, 290cm, 320cm, 340cm, 360cm, 380cm | ||

| Effective reed width: 0cm~80cm subtracted from the nominal reed with value | |||

| Weaving Capacity | Cotton or man-made fiber: 500tex(1.2Ne)~5tex(120Ne) | ||

| Slub yarn or worsted yarn: 680tex(1.5Nm)~10tex(100Nm) | |||

| Filament: 10dtex (9Td)~1650dtex (1500Td) | |||

| Allowable fabric weight: 20~850g/m2 | |||

| Weaving Speed | Rotational speed: 700r/min | ||

| Crafting speed: 450~650r/min | Depending on the reed width | ||

| Maximum weft insertion rate: 1500m/min | Depending on the reed width | ||

| Weft | Weft selector: 4~8colors (allowable colors of weft pick to be woven) Selector type: linear-motion motor or step motor type electronic weft selector |

Maximum 8 colors | |

| Weft accumulator: fixed drum type weft accumulator or electronic weft accumulator | |||

| Weft cutter: mechanical type | |||

| Power | Drive control: 7.5kw three-phase asynchronous motor, electromagnetic clutch, starter motor | ||

| Main motor: 7.5kw AC three-phase asynchronous motor | Reed width: 320cm | ||

| Shedding | High speed dobby shedding system (Its maximum allowable number of heald frames is 20.) or positive type cam shedding system(Its maximum allowable number of heald frames is 8.) | ||

| Jacquard shedding system | |||

| Weft Beating | Sley (driven by two conjugate cams on both sides of the loom) | ||

| Weft Insertion Device | Mechanical linkage of crankshaft and connection rod | ||

| Warp Let-off Mechanism | AC servo motor for continuous warp let-off motion | ||

| Single warp beam | Double warp beam | ||

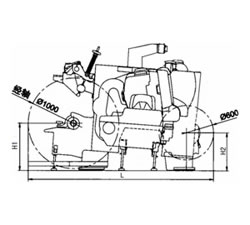

| Warp flange diameter: φ1000mm φ800mm φ700/φ500mm | |||

| Cloth Take-up | Electric servo motor for continuous cloth take-up | ||

| Cloth roll diameter : 600mm(standard) or 1200mm (with the aid of external device) | |||

| Weft density: 2~200picks/cm | |||

| Selvedge Formation | Selvedge forming device: stepper motor or linear motor | ||

| Selvedge cutter: mechanical type or electronic type(for option) | |||

| Temple: two independent temples set on both sides of the loom or one temple spanning the full width of the warp | |||

| Lubrication | Oil spray lubrication or oil bath lubrication | ||

| Stop Protector | Warp stop-motion with 6 or 8 rows of contact points | ||

| Weft stop-motion: highly-sensitive piezoelectric sensor | |||

| Other stop-motion mechanisms available to stop the loom automatically if the selvedge breaks. | |||

| Stop-indicator: The reason that may cause the loom to stop is presented on the control panel. The 4-color light will be turned on to warn users. | |||

| Automatic Functioning | Automatic loom stop at the designated point, slow-speed weft-finding, cloth-fell compensation(broken weft repair), warp tension adjustment, reset, automatic warp tension detection, loom fault display. | ||

| Electrical Control | Multi-function CPU control system for monitoring, automatic diagnosis, and information display. | ||

| Touch screen or large liquid crystal display(LCD) for two-way communication, setting or adjusting parameters, programming | |||

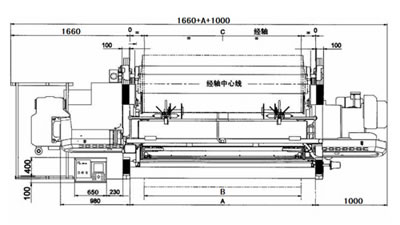

| Warp flange diamter | L | H1 | H2 |

| φ1000 | 2033 | 527 | 428 |

| φ800 | 1837 | 439 | 332 |

| Loom Specifications | |||||

| LP | A | B Fabric with Slevedge | C Warp Shaft | ||

| Maximum | Minimum | Maximum | Minimum | ||

| 170 | 2100 | 1700 | 900 | 1700 | 910 |

| 190 | 2300 | 1900 | 1100 | 1900 | 1110 |

| 200 | 2400 | 2000 | 1200 | 2000 | 1210 |

| 220 | 2600 | 2200 | 1400 | 2200 | 1410 |

| 230 | 2700 | 2300 | 1500 | 2300 | 1510 |

| 240 | 2800 | 2400 | 1600 | 2400 | 1610 |

| 260 | 3000 | 2600 | 1800 | 2600 | 1810 |

| 290 | 3400 | 2900 | 2100 | 2900 | 2110 |

| 320 | 3800 | 3200 | 2400 | 3200 | 2410 |

| 340 | 4000 | 3400 | 2600 | 3400 | 2610 |

| 360 | 4200 | 3600 | 2800 | 3600 | 2810 |

| Model NO. | RFRL31 |

| Certification | ISO |

| Type | Weaving Machinery |

| Export Markets | Global |

| Trademark | RIFA |

| Packing | Wooden Pallet |

| Standard | Reed width; 170cm~360cm |

| Origin | Liaocheng City, Shandong Province , China |

| HS Code | 84463020 |

| Production Capacity | 2000sets/Year |

Related Names

Energy Efficient Shuttleless Loom | Power Loom Supplier | Textile Manufacturing